|

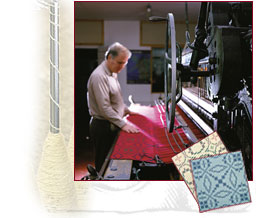

They carry out all the processes from raw wool to bedcovers, i.e. blending, carding, spinning,

doubling, dyeing, warping and weaving. We generate our own electricity using water turbines. Thomas Williams bought the mill

in 1859, it is also used. Before the Industrial Revolution, spinning and weaving was carried out by hand at home. The

woven cloth was taken to a fulling mill or "pandy" (in Welsh) to be washed and pounded before being stretched out on tenters

in the field to dry.

Trefriw Woollen Mills was such a pandy. Its position on the banks of the river Crafnant allowed

the exploitation of the soft, fast flowing water to wash the wool and cloth, and drive the water wheels which powered the

fulling hammers.

Come and you will get the cahnce to see their brilliant work.

|